In the ever-evolving landscape of modern industries, automation has emerged as a pivotal force reshaping the way operations are conducted. As technology continues to advance, automation processes have streamlined workflows, enhanced productivity, and optimized resource management. This article explores how automation is revolutionizing various sectors, contributing to increased efficiency and innovation.

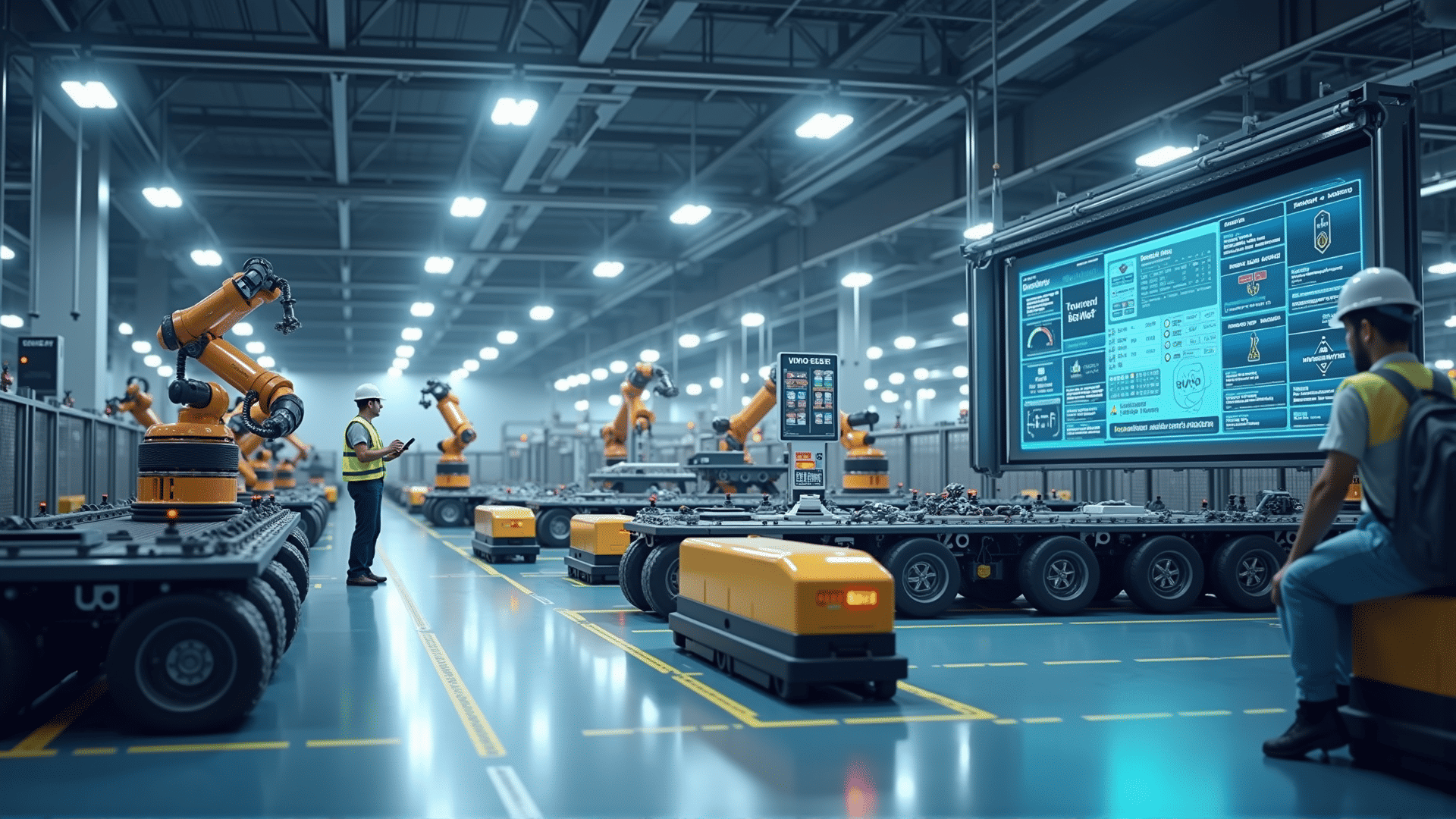

One of the primary advantages of automation is its ability to handle repetitive tasks with precision and consistency. Automated systems excel at performing tasks that would be tedious and time-consuming for humans, such as assembly line production and quality control. By deploying robots and automated machinery, industries can achieve higher accuracy in tasks like product assembly and packaging, thereby reducing errors and enhancing overall quality.

Moreover, automation enables industries to operate around the clock. Unlike human workers, automated systems do not require breaks or rest, ensuring continuous production. This 24/7 operational capability leads to higher output levels and the ability to meet rising consumer demands without compromising on quality. The integration of real-time monitoring systems further allows for the swift identification and rectification of any anomalies, minimizing downtime and maintaining seamless operations.

In sectors such as manufacturing, logistics, and agriculture, automation has paved the way for significant advancements. In manufacturing, robotic arms and conveyor systems have become integral components, enhancing production speed and efficiency. Logistics operations benefit from automated sorting systems and drones, streamlining the transportation and delivery of goods. In agriculture, automated equipment and drones facilitate precision farming, optimizing crop yield with minimal resource wastage.

The introduction of smart technologies and the Internet of Things (IoT) has further amplified the capabilities of automation. Through interconnected devices and data analytics, industries can gather valuable insights into their operations, paving the way for predictive maintenance and improved decision-making processes. This data-driven approach allows organizations to optimize their resource allocation and reduce operational costs.

However, the transition to automation is not without its challenges. Industries must invest in retraining their workforce to adapt to new technologies and collaborate with machines. Emphasizing the development of skills such as data analysis, programming, and maintenance is crucial for a smooth transition. Additionally, ethical considerations, such as ensuring the security and privacy of data, must be prioritized as automation becomes more pervasive.

Automation processes are undeniably transforming industries by enhancing efficiency, accuracy, and innovation. As automation technology continues to evolve, its integration into diverse sectors promises a future where operations are not only streamlined but also increasingly adaptive and intelligent. A holistic approach that balances technological advancement with workforce development will be key to unlocking the full potential of automation in the industrial landscape.